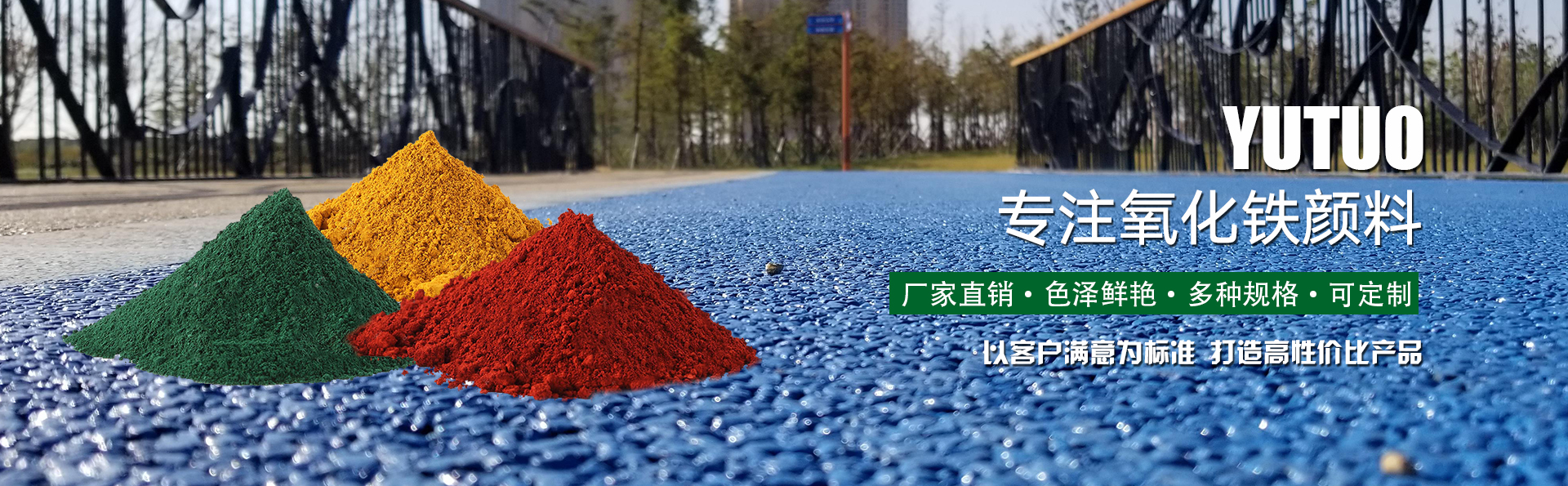

Introduction to the properties and use of iron oxide pigments

Preface

Iron oxide pigments are a class of inorganic color pigments with a large amount and a wide range of applications

It is widely used in building materials, coatings, inks, rubber, plastics, ceramics, glass products

Hardware and glass polishing, drama paint, painting, cosmetics, drug coloring, photocopying materials, catalysts, electronic industry, and magnetic memory materials for audio and video recording.

1. The pigment properties of iron oxide pigments:

1.1 High chemical stability and physical fastness:

1.1.1 Alkali resistance: resistance to alkalis and other types of alkaline substances of any concentration, especially in buildings

The commonly used cement, lime mortar, etc. are very stable, and do not pulverize cement building components, nor affect their strength.

1.1.2 Acid resistance: It has certain resistance to general weak and dilute acids, but can also gradually dissolve in strong acids, especially at elevated temperatures and concentrations.

1.1.3 Light resistance: The color does not change under strong sunlight exposure.

1.1.4 Heat resistance: It is stable within a certain temperature limit, and the color starts to change beyond its temperature limit. As the temperature increases, the degree of change becomes more significant. The temperature limits for each variety are as follows:

Iron oxide yellow gradually changes color to red phase over 130 ℃

Iron oxide red gradually changes color to deep red over 300 ℃

Iron oxide violet gradually changes color to deep red over 400 ℃

Iron oxide black gradually changes color to dark red over 100 ℃

Iron oxide brown gradually changes color to red phase over 130 ℃

Iron green gradually changes color to dark red over 200 ℃

1.1.5 Climate resistance: It is not affected by climatic conditions such as cold, hot, dry, and wet weather in the atmosphere.

1.1.6 Pollution resistant air: It is very stable in any dirty gas, such as hydrogen sulfide, carbon oxide, sulfur oxide, hydrogen chloride, nitrogen oxide, and other gases.

1.1.7 Resistance to water, oil, and solvent penetration: insoluble in water, various mineral oils, vegetable oils, ethers, esters, ketones, and other organic solvents, and free from penetration.

1.2 Have a clear color and unique tone

The color of iron oxide pigments is very clear and pure, and no other organic or inorganic pigments are used for polishing. Although not as bright and dazzling as some organic pigments or other pigments, the colors of iron oxide pigments have a unique style, with their soft and harmonic tones that are pleasing to the eye and suitable for painting in residential, public places, indoor and outdoor environments. Its solemn tone is particularly suitable for luxury buildings and grand and dignified architectural projects.

1.3 Excellent economic results

Iron oxide pigment has a high coloring power and a fine and uniform particle size, ensuring its use value. In addition, its lower price ensures the economic effect of users.

The worldwide sales volume of iron oxide pigments used for coloring is estimated to be between 600000 and 650000 tons per year. The construction and coating industries are the main users. Iron oxide is also used in non colored fields, such as ferrite, magnetic memory materials, chemical catalysts, and so on. If all these fields are included, the world's demand for iron oxide is close to 1007 tons per year, with synthetic iron oxide accounting for 70% and natural iron oxide accounting for 30%. The production capacity of the entire iron oxide industry in China has reached nearly 250000 to 300000 tons per year in 1995.

The properties and uses of various iron oxide pigments will be described below.

2.1 Iron oxide pigments for cement and building materials

2.1.1 Characteristics: Beautiful and durable in color, resistant to strong sunlight exposure and climate change, as well as alkali and mortar resistance, without damaging the properties of cement. Strong coloring power, suitable particle fineness and particle structure, and good dispersion.

2.1.2 Purpose: Suitable for coloring the following various building structures and cement products. a

Various indoor and outdoor colored concrete surfaces and architectural surfaces. Such as walls, floors, floor tiles

Roof tiles, panels, sinks, blocks, towers, colored mortar, etc. Colored surface tiles and ridge tiles.

Terrazzo and mosaic tiles, used to decorate indoor and outdoor walls, ground floors, stairs

A doorway, passageway, etc.

artificial stone. Such as artificial marble, artificial travertine, etc.

Asbestos cement for decorative wall panels, floor stone covers, roof tiles, window sills, and stairs

2.1.3 Usage:

The amount of iron oxide pigment used in concrete products is limited to 1 to 1 o%, and exceeding the high limit will result in

To reduce the mechanical strength of the product, it is generally appropriate to reduce it by 5-8%. At the same time, the iron oxide pigment does not contain lead and zinc oxides, which will affect the setting time and strength. Concrete products are sometimes required at 200. "C or higher, so black and brown iron oxides that can be converted to iron red at 180 ℃ must undergo thermal stability treatment first.".

If used on terrazzo, the bottom layer is 2-3 cm thick, and the surface layer is 15 cm thick.

2.1.4 Application: Due to its excellent weather resistance, alkali resistance, and light resistance, these properties are not compatible with other inorganic or organic pigments. Therefore, iron oxide pigments are used as coatings and colorants in building materials. Such as wall decoration, artificial marble, grinding stone flooring, and the coloring of silicate products. On the aircraft runway with colored cement or concrete pavement, the iron oxide yellow used for the outer walls of temples, and the protective walls around the imperial palace, the use of iron oxide red serves as a surface decoration.

2.2 Application in Paint

2.2.1 Characteristics: Iron oxide pigment is resistant to strong eye exposure, atmospheric impact, dirty gases (such as hydrogen sulfide), good alkali resistance, good rust resistance, good corrosion resistance, and has decorative and standard properties

Strong recognition, covering and coloring power.

2.2.2 Purpose: Suitable for coloring and protecting various coatings and paints. Such as alkyd resin, amino alcohol acid, perchloroethylene resin, polyurethane, nitro, polyester paint, etc.

In addition, it is also suitable for electrophoretic paints. Low paint, enamel, pencil paint, ready mixed paint, baking paint, anti rust paint, floor paint, waterline paint, etc. It can also be used in water-based coatings, powder coatings, and plastic coatings.

It is also used for toy paint, decorative paint, furniture paint, house paint, garage paint, parking lot paint, car topcoat, and so on.

2.3.2 Method of use: Generally, there are three steps: wetting, grinding, and dispersing (paint mixing). Iron oxide pigments, paints, and fillers are mixed evenly in a batching tank to form a coarse color paste. Different grinding equipment is used based on the different viscosities obtained by the amount of solvent added. For example, thick paste can be finely milled using a three roller mill, and thin paste can be ground using an efficient sand mill (vertical or horizontal) or ball mill. The primer is generally around 50 microns, and the finish coat is required to be around 40 microns. Then, in the paint mixing tank, add tree root, dry materials, solvents, etc. to mix and disperse the paint, match colors, adjust viscosity, etc., filter, and package the finished product.

2.2.4 Application: Iron oxide pigments have excellent weather resistance, high purity, good thermal stability, good compatibility with other components in the application system, can absorb ultraviolet rays, prevent substrate degradation, and low cost, which can be widely used in coatings and paints. Due to its strong hiding power, strong resistance to ultraviolet rays, and small water absorption, it can enhance the mechanical strength of the paint film, especially its excellent characteristics in terms of adhesion. When mixed with other anti rust pigments such as red lead and zinc yellow, it can enhance the stability and mechanical strength of the paint film, and is widely used in various outdoor paints, traffic paints, metal anti rust primers, and topcoats. Iron oxide pigments used in paints and coatings include iron red, iron yellow, iron brown, iron black, iron green, mica iron oxide, and transparent iron oxide products, among which iron red products are widely used in large quantities. Transparent iron is suitable for automotive topcoats, wood coloring, canned coatings, pharmaceutical packaging coloring, and other aspects.

2.3 Iron oxide pigments for rubber and plastics

2.3.1 Characteristics: Beautiful and generous color tone, strong coloring power, high purity, resistance to strong sunlight exposure, atmospheric impact, resistance to dirty gases, and various climatic changes. Good alkali resistance and poor acid resistance. The coating force for rubber products is quite large. It reacts in hot sulfuric acid when exposed to sunlight, air, and acids and bases, but does not change when exposed to sulfur or hydrogen sulfide. It has a reinforcing effect and prevents aging of rubber products! In molding processes where the thermal stability of plastic parts requires less critical processing temperatures. For asbestos plastic products such as brake pads and brake pads, it can increase the coefficient of friction and reduce friction loss. Economical in use.

2.3.2 Purpose: Iron oxide pigments for rubber can be applied to the following types of rubber products.

Various inner tube products: automobile inner tubes, aircraft wheel inner tubes, bicycles and rickshaw barking tires, etc.

Model products: sole, heel, bottle stopper, hot water bag, gloves, ball tire, rubber tile

And so on.

Hard products: chemical materials, insulating materials, battery trays, medical appliances, stationery products, etc.

Others: pipes, belts, leather bags, electric wires, waterproof tarpaulins, etc.

Iron oxide pigments for plastics are suitable for coloring the following types of plastic products.

Thermosetting plastics: urea formaldehyde plastics, melamine resin plastics, phenolic plastics, foam plastics, asbestos plastics (brake pads, brake pads, etc.) products

Thermoplastic; Polystyrene plastic, polyvinyl chloride plastic (colored film, plastic floor

Board), polyethylene molding materials, etc.

2.3.3 Method of use: The use of iron oxide pigment on rubber: Generally, after washing and refining raw rubber, mechanical treatment is used to obtain the necessary plasticity of the rubber, and then vulcanizing agent, iron oxide pigment, zinc oxide, calcium carbonate, and other fillers are added to control to obtain the rubber raw material. Reprocess and shape various rubber products.

Method of using iron oxide pigments on plastics: such as on asbestos plastic brake pads

"The product is mixed with resin, asbestos, and iron oxide pigments, adjusted to a certain viscosity with a solvent, kneaded, and dried. Then, the asbestos plastic is placed in a press I to form a wood grain decorative paper, and iron oxide pigments are used for coloring PVC plastics. The method is to first mix the iron oxide pigments and plasticizers (such as zinc benzoate) into a thick paste (the amount is divided into 2:1,11.1, 1: 0.5, etc. based on the amount of oil absorption),", Place it on a flat roller machine or three roller machine for grinding (with transparent and opaque films), and then blend each component and color paste evenly according to the transparent or opaque film formula until no color filaments, spots, or particles are produced. Place this colored PVC paste in a coater and evenly coat it onto a glass plate. After it is stationary, dried, and defoaming, place it in a 180 ℃ blower oven for plasticization. After 10 minutes, take it out and cool it to form a colorless or colored PVC film.

2.3.4 Application: In the application of rubber and plastics, iron oxide red, which does not contain heavy metal ions such as copper and manganese, can be used in aircraft tires to prevent rubber aging. Iron oxide pigments have the characteristics of strong coloring power and pure color, and are used as colorants and fillers in PVC plastic flooring, PVC colored films, thermosetting plastics, such as carbide powder, bakelite powder, and thermoplastic plastics such as polyolefins. Iron oxide pigments, such as color masterbatches or slurry preparations, will be more popular in the materials industry. Due to the non-toxic nature of iron oxide pigments, transparent iron oxide pigments are used abroad for coloring plastic beer bottles, pharmaceutical vials, and food packaging plastics. They are a new type of blending pigments for plastics.

2.4 Iron oxide for ferrite magnetic materials

4.1 Characteristics: High chemical purity, fine and uniform particles, spherical structure, large specific surface area, generally around 10-15 square meters/gram, preferably honeycomb shaped crystal form, strong chemical activity, perfect solid phase reaction, low chemical impurities and soluble salts.

It is suitable for synthesizing oxides of one or more other metal elements, such as oxides, hydroxides, carbonates, or oxalates, by solid state reactions to form ferrite magnetic materials.

2.4.2 Purpose: Iron oxide is an oxide of various other metal elements and can be made into different crystal structures under different reaction conditions to meet various application requirements. Such as soft magnetic ferrite products, permanent magnetic ferrite systems, spin magnetic ferrite products, short magnetic ferrite products, and pressure magnetic ferrite products.

2.4.3 Method of use: Place iron oxide and oxides, hydroxides, carbonates, oxalates, etc. of one or more other metal elements in a certain proportion in a ball mill, mix and grind them finely, take them out for drying, and then place them in a high-temperature furnace of 700 to 900. Heat and pre calcine at C, then finely grind the pre calcined powder into a press mill for molding, and then move it to 1100~1400 ℃ for roasting and heat treatment. After delicate processing, the product is made into a ferrite system.

2.4.4 Application: The application of iron oxide in the electronic industry. The iron oxide powder has the characteristics of fine and uniform, large specific surface area, reaching 10-15 square meters/gram, and strong chemical activity. It is one of the important raw materials for ferrite magnetic materials. The ferrite formed by combining iron oxide with metal elements such as manganese, zinc, nickel, and magnesium has a spinel crystal structure, and is widely used in various magnets and microwave applications. For magnetic iron oxide magnetic powder, it has good chemical stability and thermal stability, as well as excellent performance in coercivity magnetic tape loops, and has been widely used in various types of magnetic tapes, computers, memory materials, magnetic plastics, and flaw detection magnetic powder products such as Y-Fe: 03,

It is a spinel type needle shaped crystalline structure of iron oxide, coupled with its submicron particle size, making it a good material for making audio and video tapes. Due to its needle like particles, during the coating process, magnetic fields can be applied to obtain better orientation, making it a key material for magnetic recording materials. It can be used for surface flaw detection of audio and video tapes, instrument tapes, and other materials such as magnetic plastics, magnetic pole plates for television tuning centers, convergence plates, and steel products.

Currently, the varieties produced in China include spherical magnetic particles for flaw detection and high-efficiency magnets for magnetic plastics

Powder, needle shaped magnetic powder for sound recording tapes, cobalt infiltrated magnetic powder for video tapes, and microparticle magnetic powder for instrumentation tapes.

2.5 Iron oxide for metal flaw detection

2.5.1 Performance: Iron oxide (magnetic iron oxide) used for metal flaw detection has the following characteristics; There is a homogeneous buccal granular tissue with a magnetic gradient.

2.5.2 Purpose: Used to inspect various ferrous metal materials, peaches, and parts of various magnetic cauldrons (using its ferromagnetism to inspect cracks and blisters in various steel materials, and to open and display ballast). It can be used to inspect rough and cracked lines to avoid various accidents. It is used to inspect products such as steel, steel storage, and chisel shafts, gears, automotive and aircraft parts.

2.5.3 Method of use: Magnetic powder is used to produce liquid materials for flaw detection. The method is to prepare magnetic powder slurry with kerosene (1:1). During the preparation process, it is necessary to treat the magnetic particle particles in a suspension state in solution. Therefore, first carefully mash the magnetic particle with a small amount of kerosene, and then dilute the mixture to 3.5% magnetic particle per liter_ 4.5 kg.

2.6 Iron oxide for polishing glass products and glass hardware

2.6.1 Characteristics: Used for glass products and glass and hardware products. The characteristics of iron oxide used for polishing products are: suitable particle fineness and particle structure, good polishing ability and smoothness, and excellent hardness of particle particles. The chlorine content of iron oxide pigments used in glass products must be less than 01.2%, and those with a content less than 0.1% are more suitable..

2.6.2 Purpose: Glass products, flat glass (float production), optical glass.

Polishing of glass products; Flat glass, glasses, optical lenses, clock glass, magnesium glass products, flat plexiglass, etc.

Hardware polishing: instruments, medical devices, daily necessities, textile products and products, steel needles, flashlights, pen tips, pen tubes, gold and silver products, etc.

Other aspects: various polishing paste products.

2.7 Iron oxide used as a chemical catalyst

2.7.1 Characteristics: Iron oxide used for chemical catalyst reactions has the following characteristics: fine and uniform molecular particles, large specific surface area, strong catalytic activity, low chemical impurities and soluble salts, good activation, and high conversion. Iron oxide catalysis

热门关键词: